Rotary Arm Pallet Wrapping Machine

X1000mp

X1000mp Specifications

Maximum wrapping speed

25-30loads/ Hour Speed

Max pallet size

1.2x1.2m

Maximum Wrapping Height

2000mm

Wrapping Speed

3-12RPM(Adjustable)

Standard Film Width

500mm

Constant Film Delivery Force

Standard

Standard Pre-Stretch

250% pre-stretch

Film Capacity

250mm Diameter

Film Delivery System

Motor control

Up and Down Drive System

Belt drive

Top pressure function

optional

Machine Size

2.68x1.1x3.1m

Voltage

220V/50/60HZ

Machine Weight

600KG

Control

PCB(SMART WASP PATENT)

Position sensor

SICK(Germany)

Photoelectric sensor

Autonics

Travel Switch

OMRON(Japan)

Rotary drive Motor

SMARTWASP Brake Motor

Touch screen

X-Line(SMART WASP)

Switch

Schneider

Up and Down Motor

SMARTWASP

Special Process

Introduction

Frame

Steel+Aliminum profile

Printing

Metallic Paint

Rotary Driveway

Slewing Bearing

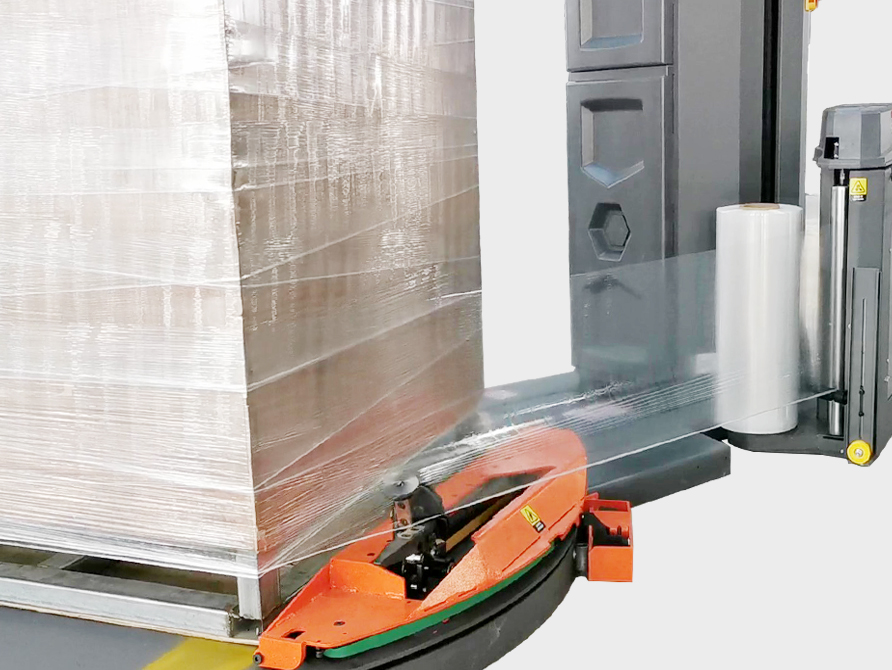

X1000mp Features

X1000mp (place pallet directly on the floor)

- No ramp required for pallet loading

- Unlimited loading weight

- Minimal installation space needed

Durable Wrapping Arm

The X1000mp utilizes a Slewing Bearing Drive for its rotary arm, ensuring durability, quiet operation, and no future maintenance requirements.

High Level Wrapping Safety

If the arm touches anything during wrapping, the whole machine will stop immediately.

Intelligent operation system + PCB control system

The machine features an operational guide solution, instructing you on the next steps for operation. Should any issues arise, the screen provides immediate solutions for troubleshooting. With PCB control, maintenance is significantly simplified.

Frequency Asked Questions

How does a Rotating Arm Stretch Wrap Machine work?

Rotating arm stretch wrappers can wrap a high volume of loads that other machines cannot. The lack of a turntable allows you to place non-standard size and weight pallets on the floor in the wrapping zone via a forklift or pallet jack.

Once the pallet is in place, the operator then pushes a button on the control panel, and the machine immediately begins wrapping the pallet. The rotating arm then follows a preset wrap program to ensure the stability and security of the load.

Depending on the model, the machine can wrap anywhere from 25 per hour up to 300 per day.

Benefits of Rotary Arm Stretch Wrap Machines

A rotary arm stretch wrap machine allows the pallet to remain stationary during the wrap cycle. This offers several advantages:

Extremely Light Loads—On a standard turntable pallet wrapper, very light loads can fall off during the wrapping process. A rotary arm machine allows the pallet to remain securely in place, thereby preventing the load from spilling.

Extremely Heavy Loads—Turntable pallet wrappers have a max load weight. Rotary arm stretch wrappers do not have a turntable and, as such, no weight limit.

Washing Issues—Some shipping areas require regular washdowns. You can raise the rotary arm of the wrapper to avoid it getting wet during the cleaning process.

Unstable Loads—You run the risk of spilling or damaging an unbalanced load if you put it on a turntable wrapper. Rotary stretch wrap machines do not have turntables and can quickly wrap non-standard-size pallet loads.

Tall Loads—Taller loads run a risk of getting damaged when using a turntable stretch wrapper. A rotary arm stretch wrapper allows for the wrapping of much higher pallets.

20+ years in stretch film manufacturing. Now offers a one-stop solution: wrapping machines and film adjustment services to enhance your productivity. Our expertise ensures comprehensive packaging solutions for your business growth.

Contact

No.12, Lorong Seri Gambut 1,

Off Jalan Kebun,

41000 Klang,

Selangor.

About

Info

Social media

Youtube

© Copyright Vincco Success Sdn Bhd. All Rights Reserved.